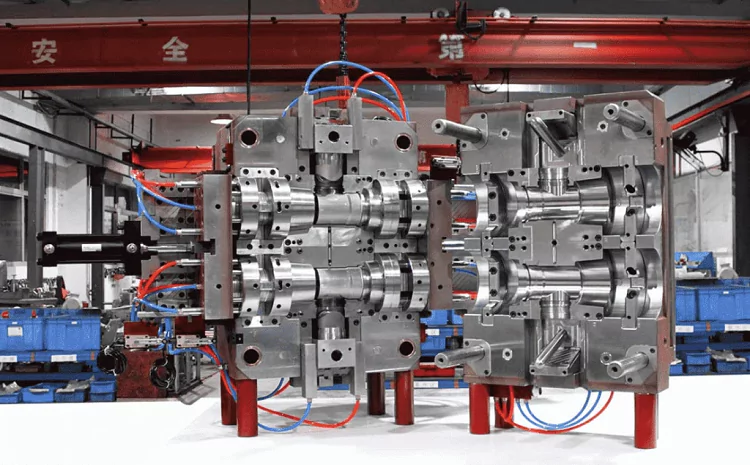

Injection molding is a widely-used manufacturing process where molten material is injected into a mold to produce durable and precise parts. For businesses across industries like medical, electronics, automotive, and household appliances, finding a reliable injection molding manufacturer is crucial to producing high-quality products. HITOP, a leading injection molding manufacturer based in China, is known for its expertise in mold design, rapid prototyping, and engineering solutions tailored to global clients.

In this article, we’ll explore the benefits of injection molding, the services offered by HITOP, and how their solutions can meet the demands of various industries.

Key Takeaways

- Injection molding is a manufacturing process used to create durable, precise parts for a range of industries.

- HITOP is a trusted injection molding manufacturer, offering services like mold design, rapid prototyping, and custom manufacturing solutions.

- HITOP is committed to producing high-performance molds and providing personalized service to clients worldwide.

What is Injection Molding?

Injection molding is a manufacturing process that involves injecting molten material, usually plastic, into a mold. The material then cools and hardens to take the shape of the mold, producing a part that is precise and durable. This process is used to create a wide variety of products, from small components to large industrial parts.

Injection Molding Process

The injection molding process involves several key steps:

- Material Selection: Choosing the right material is crucial for achieving the desired strength and durability.

- Mold Design: A well-designed mold ensures the part is produced with precision.

- Injection: Molten material is injected into the mold at high pressure.

- Cooling: The material cools and hardens, taking the shape of the mold.

- Ejection: The finished part is ejected from the mold and ready for use.

HITOP: A Leading Injection Molding Manufacturer

HITOP is a top-tier injection molding manufacturer based in China, offering mold design, rapid prototyping, and custom manufacturing solutions to clients worldwide. With years of expertise in injection molding, HITOP has established itself as a go-to partner for businesses across various industries, including medical, electronics, household appliances, airline, and auto industries.

Why Choose HITOP?

HITOP offers several advantages that make them a standout injection molding manufacturer:

- High-Performance Molds: HITOP creates durable, long-lasting molds that meet the high-performance demands of industries such as automotive and medical.

- Custom Solutions: Whether you need injection molding for a large-scale production or small batches, HITOP offers personalized services tailored to your project’s needs.

- Advanced Technology: With cutting-edge equipment and technology, HITOP ensures precision and consistency in every part produced.

Mold Design and Rapid Prototyping

One of HITOP’s specialties is mold design and rapid prototyping. Mold design is a critical step in the injection molding process because it determines the quality and precision of the final product. HITOP works closely with clients to design molds that meet exact specifications and performance standards.

Their rapid prototyping service allows clients to quickly test and refine their designs before committing to large-scale production. This process helps businesses reduce time to market and ensures the final product is of the highest quality.

Industries Served by HITOP

HITOP serves a wide range of industries, each with unique requirements for injection molding. Some of the key industries include:

Medical Industry

The medical industry requires precision, reliability, and durability in every part produced. HITOP provides custom injection molds that meet stringent medical standards, ensuring that components used in medical devices are safe and effective.

Automotive Industry

In the automotive industry, the demand for durable and high-performance parts is constant. HITOP’s injection molding solutions provide automotive manufacturers with parts that are built to last, ensuring safety and reliability in vehicles.

Electronics and Household Appliances

For electronics and household appliances, precision and aesthetics are crucial. HITOP creates molds that produce sleek, functional components, enhancing both the performance and appearance of electronic products.

Why HITOP’s Injection Molding is Essential for Businesses?

For businesses looking to produce high-quality parts, HITOP’s injection molding services offer several key benefits:

- Cost Efficiency: By creating injection molds that last through long production runs, HITOP helps businesses reduce overall production costs.

- Scalability: Whether you need small or large-scale production, HITOP’s manufacturing processes can accommodate different quantities with precision.

- Time-Saving: With rapid prototyping and efficient production, HITOP helps businesses bring products to market faster without compromising on quality.

Customer-Centric Approach

HITOP is dedicated to providing personalized service to meet the unique needs of every client. From the initial mold design to final production, HITOP works closely with businesses to ensure every aspect of the project meets the highest standards.

Conclusion

For companies seeking reliable and high-performance injection molding solutions, HITOP stands out as a leading manufacturer in the industry. With a focus on precision, durability, and customization, HITOP serves a wide range of industries, including medical, automotive, and electronics. Their expertise in mold design, rapid prototyping, and advanced manufacturing technologies ensures that businesses can trust HITOP for all their injection molding needs.

Visit HITOP to learn more about their innovative services and how they can help bring your product designs to life through superior injection molding solutions.