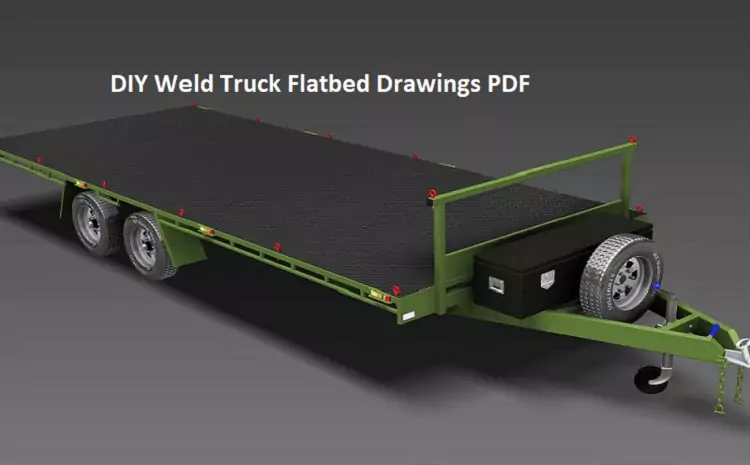

Truck flatbeds are essential for many DIY enthusiasts, especially those who rely on their trucks for hauling and heavy-duty work. Having a flatbed instead of a standard truck bed offers more versatility, especially if you often load and unload heavy materials. But why stop at buying a pre-made one when you can build your own?

In this guide, we’ll walk you through how to build your custom truck flatbed from scratch, including access to DIY weld truck flatbed drawings in PDF format to make your job easier. Whether you’re experienced with welding or a beginner looking for a new project, this article is packed with everything you need to know.

Understanding the Basics of Truck Flatbeds

What is a Truck Flatbed?

A truck flatbed is an open, flat platform installed at the back of a truck. Unlike traditional truck beds with side panels, flatbeds offer an unobstructed area for easy loading and unloading. They are especially useful for carrying oversized loads, equipment, or other items that don’t fit within the confines of a standard truck bed.

Advantages of Flatbeds Over Traditional Truck Beds

Flatbeds are popular among contractors, farmers, and outdoor enthusiasts. They offer:

- Greater surface area for loading

- The ability to transport irregularly shaped items

- Easy access from all sides

Why Choose DIY for Your Truck Flatbed?

Customization Options

One of the biggest reasons to go the DIY route is the ability to fully customize your truck flatbed. From material choice to dimensions, you control every aspect of the build. This flexibility is especially useful if you have specific needs that standard flatbeds can’t meet.

Cost Efficiency

Another compelling reason to build your own flatbed is the cost savings. While a pre-made flatbed can cost thousands of dollars, building one yourself can save you a significant amount, especially if you already have access to tools.

Satisfaction of Personal Work

There’s something immensely satisfying about crafting your own flatbed. Not only do you save money, but you also get the satisfaction of knowing that every weld, cut, and bolt was done with your own hands.

Materials and Tools Required for a DIY Weld Truck Flatbed

Essential Materials

- Steel or Aluminum: Steel is the most common material for flatbed frames due to its strength, but aluminum is a lighter alternative.

- Lumber: For decking, many prefer wood, although steel decking is also an option.

- Bolts and Screws: To secure the flatbed to the truck and fasten components together.

Necessary Tools

- Welder (MIG or TIG)

- Angle Grinder

- Measuring Tape

- Metal Cutter

- Safety Equipment (gloves, goggles, etc.)

Where to Source High-Quality Materials

You can find steel and aluminum from local metal suppliers or specialty stores. Make sure to get durable, rust-resistant materials for longevity.

Planning and Designing Your Truck Flatbed

Measuring Your Truck’s Dimensions

Before starting, it’s crucial to take accurate measurements of your truck’s frame and bed area. This ensures your flatbed will fit properly once built.

Sketching a Blueprint for Your Flatbed

Once you have the measurements, sketch a basic blueprint. If drawing isn’t your strength, don’t worry! You can find professional-grade truck flatbed drawings in PDF format online, which will provide precise dimensions and welding points.

Understanding Weld Types for Your Flatbed

MIG Welding vs. TIG Welding

MIG welding is often preferred for truck flatbed projects due to its speed and efficiency, while TIG welding is ideal for more detailed, precision work.

Step-by-Step Guide to Welding the Truck Flatbed

Frame Assembly

Start by welding the outer frame. Ensure your welds are clean and secure, as this is the foundation of your flatbed.

Attaching Cross Members

Next, weld cross members inside the frame to add structural support. This ensures that the flatbed can handle heavy loads without buckling.

Installing the Deck

Lay down your decking material, either wood or steel, and bolt it into place. Make sure the deck is flush with the edges of the frame for a smooth finish.

Mounting the Flatbed onto Your Truck

Once your flatbed is complete, it’s time to attach it to your truck. Use bolts to securely fasten the flatbed to the truck frame, making sure everything is level and stable.

Safety Precautions for Welding Projects

When welding, always wear protective gear, including gloves and goggles. Ensure your workspace is well-ventilated and free of flammable materials.

Conclusion

Building a DIY truck flatbed is a rewarding project that offers both practical benefits and personal satisfaction. With proper planning, the right tools, and access to professional-grade drawings, you can create a flatbed tailored to your exact needs.